- High-performance product with new functions

- Realizes unprecedented functionality through our unique technical development capacity.

- Safe and secure lighting

- Realizes visualization and predictive maintenance of lighting through monitoring its brightness and temperature.

- Making high quality available at a low cost

- Optimal mass-production design makes highquality products available at low cost.

- ProblemIndividual LED brightness varies

- SolutionCurrent correction circuit corrects LED forward current variations to achieve uniform brightness.

- ProblemBrightness fluctuates due to lighting heat and ambient temperature changes

- SolutionTemperature compensation circuit corrects brightness fluctuation due to rising temperatures after lighting comes on and ambient temperature changes.

- ProblemLighting brightness cannot be numerically controlled

- SolutionLuminance monitor function allows numerical brightness control, with upper/lower limit settings enabling alarm output.

- ProblemBrightness varies even with the same lighting at the same light intensity value

- SolutionAbsolute luminance values based on factory default data can be used as indices to enable uniform brightness across lighting.

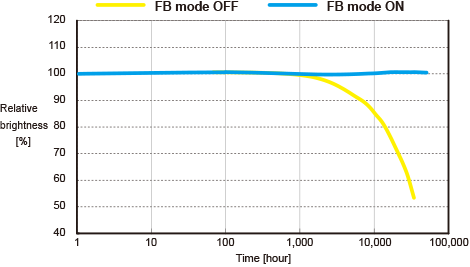

- ProblemRegular brightness adjustment is required as the LED ages

- SolutionBrightness is automatically adjusted to maintain initial settings.

What are FALUX and FALUX sensing?

CCS FASTUS LED lighting is equipped with a proprietary technology designed to maintain brightness automatically over long periods by detecting the temperature and brightness of the lighting.

Problems with LED Lighting

Problem 1: Variations in brightness between individual LEDs

Because variations in forward voltage of individual LED can affect the brightness of the LED, the forward voltage must be aligned through sorting or some other means.

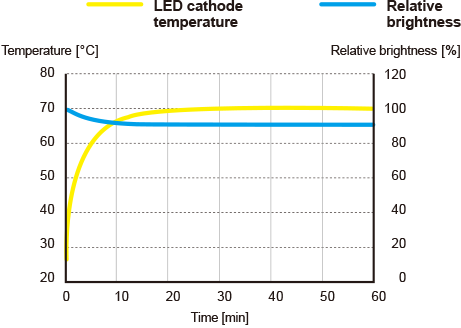

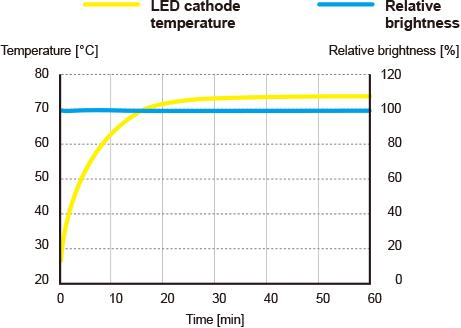

Problem 2: Fluctuations in brightness due to heat generated by the LED

When LED lighting is turned on, the LED itself generates heat, causing temperature to rise.

As the internal or ambient temperature rises, the brightness decreases.

Applicable Series

Problem 3: Management of long-term variations in brightness

After 40,000 hours of use, the brightness of LED lighting drops by 50%. This means that brightness must be adjusted when used for long periods.

Applicable Series

Outline of FALUX and FALUX sensing

Features of FALUX

Built-in “FALUX” circuit to correct variations in brightness

*Included in all models.

Using the constant current circuit dependent on the input voltage, variations in the forward current of individual LEDs are corrected for uniform brightness.

Meanwhile, the temperature compensation circuit compensates for fluctuations in brightness due to increases in temperature after lighting or changes in the ambient temperature.

- FALUX not included

- In order to reduce LED forward voltage variations, the LEDs needed to be sorted according to their Vf measurement. Moreover, illumination efficiency dropped as the temperature increased, reducing the brightness.

-

- FALUX included

- The brightness of each LED is fixed, virtually eliminating variations in brightness following increases in temperature. Whether with continuous illumination or ON/OFF control, brightness remains fixed.

-

Features of FALUX sensing

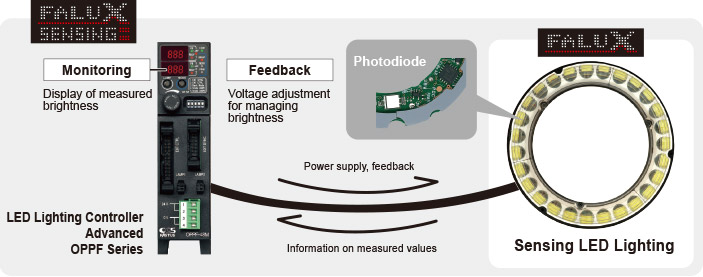

Equipped with “FALUX sensing” for monitoring brightness and temperature through sensing

LED brightness sensing is performed using multiple built-in photodiodes.

This allows for accurate measurement of LED brightness not only during continuous illumination but also with short period illumination.

Absolute brightness is stored in the lighting’s internal memory to allow for instrumental error adjustment.

“FALUX sensing” also makes it possible to measure both the LED brightness of lighting and the internal temperature, and then to monitor those measurements on the power supply side.

Based on the monitored values, feedback control can also be performed from the OPPF Series controller, making it possible to maintain the factory default brightness for around 40,000 hours.

Products

LED Lighting

OPR Series

Sensing Ring Lighting

OPR-SF Series

Sensing Ring Lighting (with Temperature Protection Circuit)

OPB-S Series

Sensing Bar Lighting

OPF Series

Sensing Backlight

OPX Series

Sensing Coaxial Lighting

OPS-S Series

Sensing Spot Lighting

HPDS / HPDM Series

Sensing Dome Lighting

HPRS / HPRM Series

Sensing Diffused Lighting

Controllers

Options

CB Series

Cable

RCB Series

Cable

Technical Guide

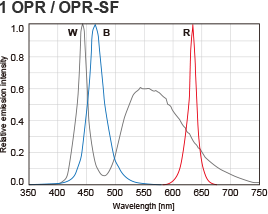

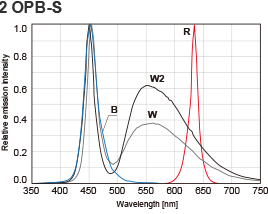

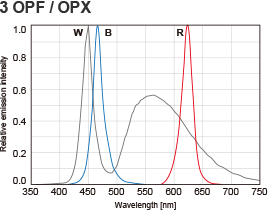

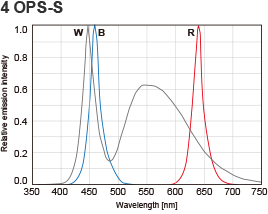

Emission spectrum diagram

The lamp emission spectrum distributions for each LED lighting series are displayed here.

The horizontal axis is the wavelength (nm), and the vertical axis is the relative emission intensity.

Data is for reference purposes.

Please note that actual products will vary slightly.