OPF Series

foreign object detection of transparent and metal workpieces

Features

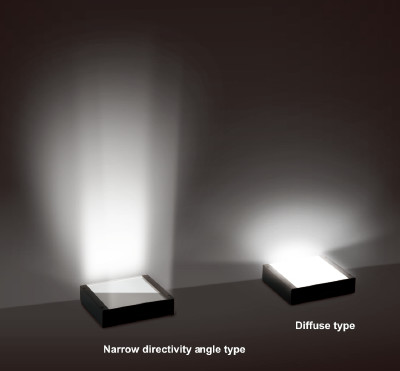

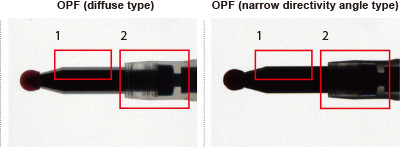

[An industry first!] Narrow directivity angle type and diffuse type available

The OPF Series is available as a narrow directivity angle type or as a diffuse type, allowing for selection of the directivity angle that best suits the target.

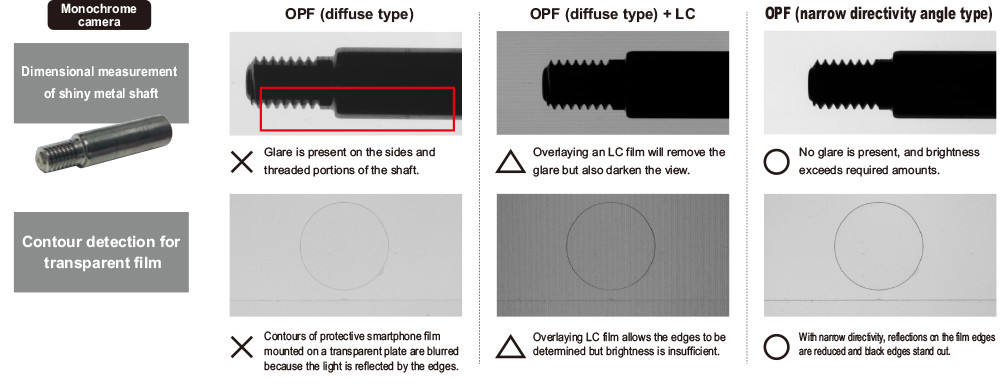

Using the industry’s first prism sheet, the narrow directivity angle type allows for clear contour extraction with transparent workpieces and metal workpieces that cause glares, targets that were conventionally difficult to handle.

Narrow directivity angle type for powerful contour extraction with transparent or glossy targets

OPF Series lighting is equipped with a proprietary prism sheet on the diffusion plate for a narrow directivity angle (half-value angle of ±17°) equivalent to that offered by conventional light control (LC) film.

Illuminating from the rear with a narrow directivity light angle prevents unwanted reflected light for projection of a crisp silhouette that is not affected by surface conditions.

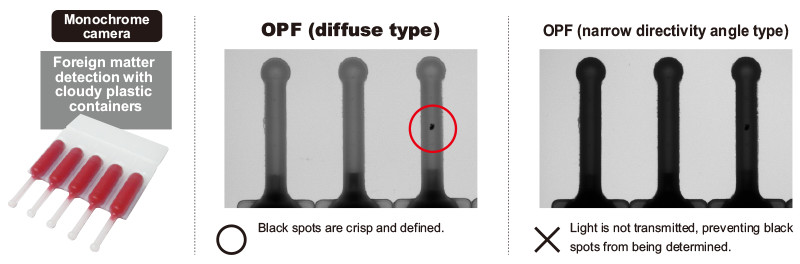

Diffuse type for penetrating scattering workpieces

When detecting foreign matter within workpieces that scatter light, including non-woven fabric and cloudy plastic, a diffuse type is available as an upward-compatible product for conventional OPSM models.

With highly uniform light that is 2.5 times brighter than conventional models, the diffuse type easily penetrates scattering workpieces and displays the shadows of foreign matter.

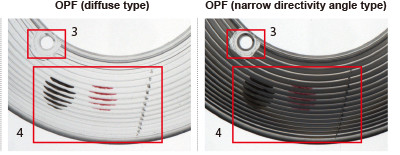

Selective use of directivity angles even with color camera

1 The narrow directivity angle type captures contours on shiny cylindrical metal with no glare.

2 The diffuse type’s ability to permeate plastic with mixed metal?plastic areas makes it possible to capture even interior metal components.

3 The narrow directivity angle type is capable of capturing clear images of the contours of the countersunk portions of screw holes.

4 Dirt and scratches are clearly displayed using the diffuse type and can be shown in separate red and black colors.

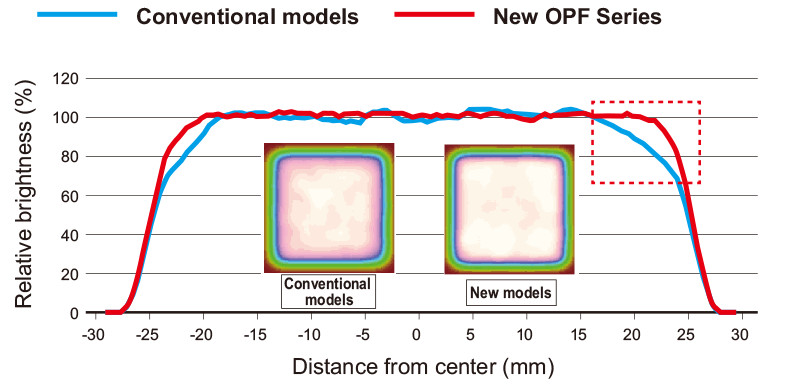

Correction of peripheral decreases in brightness

Thanks to an optimized arrangement of LEDs, not only uniformity but also brightness deterioration of the peripheral areas has been improved.

This allows for a larger inspection area than that offered by conventional models to be ensured even with the same light-emitting surface size.

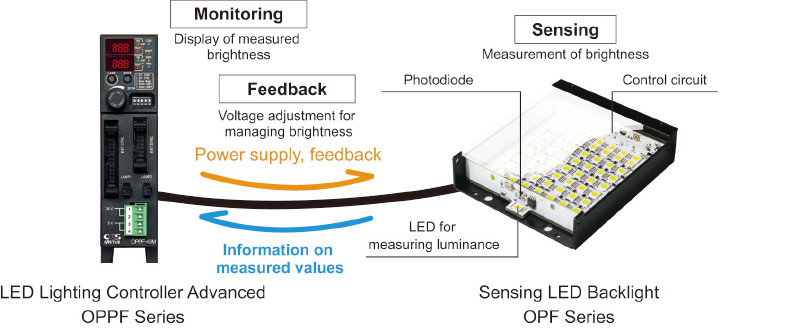

Sensing lighting with automatic brightness management

Sensing lighting with automatic brightness management

OPF Series devices include CCS FASTUS’s “FALUX sensing” technology. The built-in photodiodes are used to monitor the brightness in order to provide feedback on long-term brightness deterioration, making it possible to maintain the factory default brightness for around 50,000 hours. This helps reduce maintenance costs during operation.

The OPF Series also has LEDs and photodiodes for measuring brightness built in to the housing frame, which allows for accurate measurement of luminance without being affected by extraneous light noise. Control circuitry mounted on the inner wall also helps keep lighting compact.

Built-in “FALUX” circuit to correct variations in brightness

Built-in “FALUX” circuit to correct variations in brightness

The OPF Series is equipped with “FALUX” proprietary technology capable of correcting reductions in luminance due to increased temperatures.

This correction function is activated within the lighting itself by analyzing the temperature inside the lighting device.

Applications

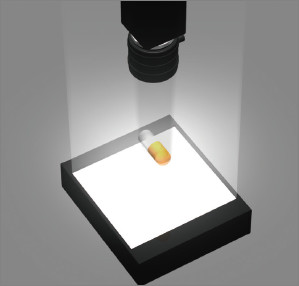

Appearance inspection of transparent capsules

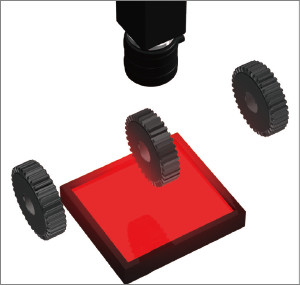

Gear processing inspection

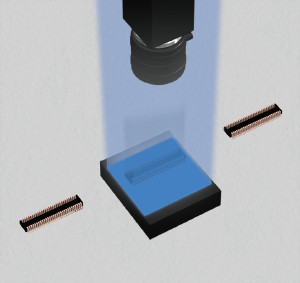

Dimension inspection of connector leads

Products

-

Machine Vision Applications

Ring

Low-angle Ring

Waterproof Ring

Bar (Area)

Low-angle Square

Flat

Flat Dome

Line Pattern

Dome

Coaxial

Cylinder

High Power Strobe

UV Lights [Ultraviolet Lighting] / Violet Light

IR Lights [Infrared Lighting] (under 1000nm)

IR Lights [Infrared Lighting] (over 1000nm)

Spot

Fiber Heads

Light Source Unit

Line (Convergent Lighting)

Line (Diffused Lighting)

Line (Oblique Angled Lighting)

Reference Light Source

Lights for Fringe Interference Inspection

Custom Order Product

Intensity Control Units [Light Units with Intensity Control Unit ]

OLED(CCS-LT)

Effilux Products

Basler Camera Light Series

- BCL Series (Bar Light)

- BCR Series (Ring Light)

- BCBL Series (Flat Light)

- BCF Series (Flood Light)

- BCL Series (Bar Light) Diffusion Plates

- BCR Series (Ring Light) Diffusion Plates

- BCF Series (Flood Light) Transparent Plate

- BCL Series (Bar Light) Light Polarizing Plates

- BCR Series (Ring Light) Polarizing Plates

- BCF Series (Flood Light) Polarizing Plates

- BCR Series (Ring Light) Light Adapter

- BCL Series (Bar Light) Light Bracket

- Basler Camera Light dedicated cable

-

Control Units

Digital Control Units

Strobe Unit

High Power Strobe Control Unit

PoE Enabled Controller

Controller with EtherNet/IP Interface

LED Light Controller

Control Units [for the HLV Series]

High-capacity Constant-current Control Units

High-capacity Analog Control Unit

Control Units [for CCS AItec]

-

Cables

Straight Cables

2-way Cables

4-way Cables

Robot Cables

2-way Robot Cables

4-way Robot Cables

Straight Cables [EL connector type]

2-way Cables [EL connector type]

Extension Cable [for PF Series]

Straight Cables for metal connector (7 pins)

Straight Cables for metal connector (37 pins)

Straight Cables for M12 connector

External Control Cables

Relay Connector

AC Power Cable

-

Options

Filters

Diffusion Plates

- Diffusion Plates [for Ring Lights]

- Diffusion Plates [for LDR-PF Series]

- Diffusion Plates [for LDR-PF-LA Series]

- Diffusion Plates [for Low-angle Ring Lights]

- Diffusion Plates [for Bar Lights]

- Diffusion Plates [for LDL-PF Series]

- Diffusion Plates [for HLDL3 Series]

- Diffusion Plates [for LB Series]

- Diffusion Plates [for Coaxial Lights]

- DF Series

- DF80 Series

Polarizing Plates

- Polarizing Plates [for Ring Lights]

- Polarizing Plates [for LDR-PF Series]

- Polarizing Plates [for Bar Lights]

- Polarizing Plates [for LDL-PF Series]

- Polarizing Plates [for HLDL3 Series]

- Polarizing Plates [for LB Series]

- Polarizing Plates [for Coaxial Lights]

- Polarizing Plates [for IR Series Infrared Lights (over 1000-nm type)]

- PL Series (FASTUS)

Light Control Films

Protective Plates

Adapter [for the CSR Series]

Lens Attachment Rings

Fixtures

Fixtures

Converter

Coaxial Units

Reflection Plate

Condenser lens

-

Lenses

Telecentric Lenses

Macro Lenses

-

Software Tools

Program for controllers

Version Upgrade for controllers

Application note for controllers

-

Agri-Bio Lighting

LED Light Units for Plant Research

ISL-150X150 Series Unit

ISL-150X150 series cables

-

Human Vision Inspection and Microscope Applications

LED Light Units for Microscopes

Request Free Trial

Request Free Trial Request Quotation

Request Quotation Inquiry Form

Inquiry Form Locations

Locations