LB Series

LB Series Diffused Bar Lights

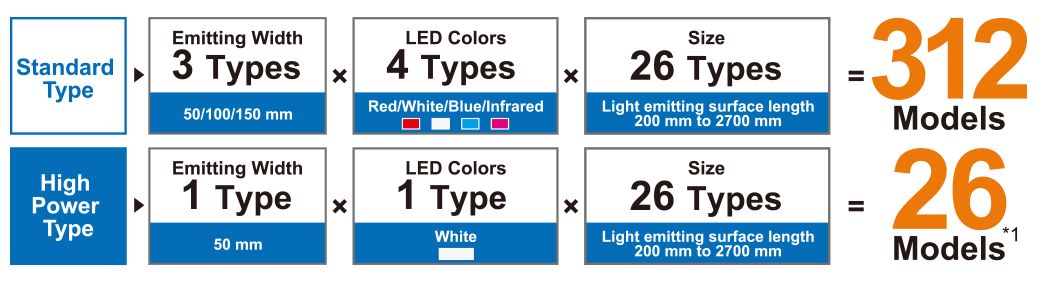

Multipurpose x Multiple Models 338 Models Total

A wide variety of lighting options are available to match the inspection environment

Features

Wide lineup

Total of 338 Models

Choose emitting width, wavelength, and size

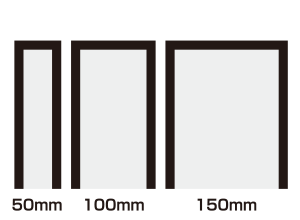

Choose from 3 emitting widths

Three emitting widths (50 mm, 100 mm, and 150 mm) can be selected according to the application.

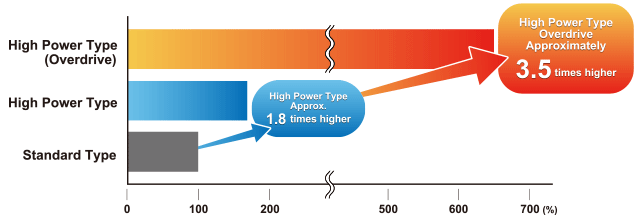

High power type with overdrive also available

Overdrive is only available for high power type sizes 200 to 700.

Model: LB-H-□□X50SW [□□=200 to 700]

The data included is for reference only. Actual values may vary.

Example

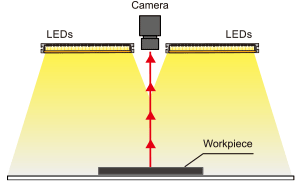

Bright field

Backlight

Diffused dome illumination

Wide-range uniform illumination

Application Examples

Various uses depending on the application

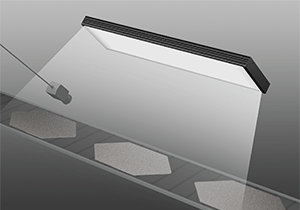

Bright field

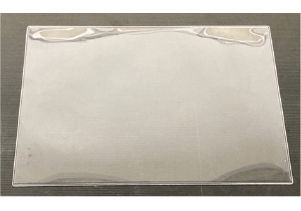

Visual inspection of satin metal

Various foreign contamination, presence inspection, etc.

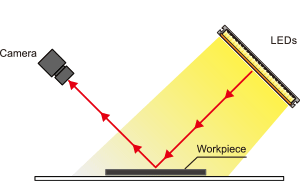

Example Configuration

Diffused lighting is illuminated from an angle, and the specular reflection light is observed. Light emitting surface width can be selected to match the workpiece and characteristics.

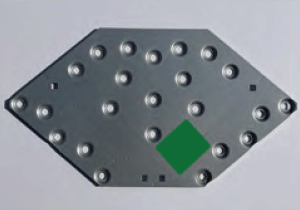

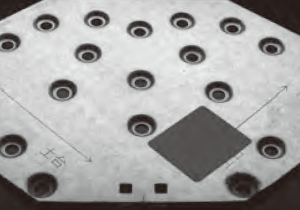

Satin metal sheet ID mark inspection

Workpiece

LB-300X150SW

Uniform illumination of wide satin surfaces for clear ID mark imaging.

Image

Transparent workpiece surface inspection

Workpiece

LNSD-300SW(A)

For highly deflective workpieces, brightness is not uniform.

LB-300X50SW

Wide light-emitting surface reduces the effect of deflection for uniform brightness throughout the entire image.

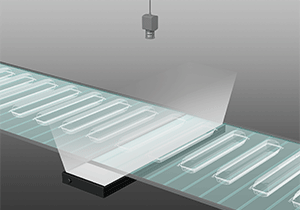

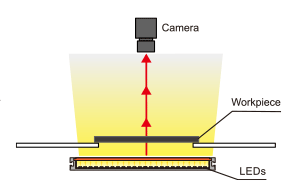

Backlight

Foreign contamination inspection on sheet

Film scratch inspection, etc.

Example Configuration

Diffused lighting is illuminated from the back of the workpiece. Suitable for translucent container foreign contamination inspection, liquid level inspection, silhouette inspection, etc.

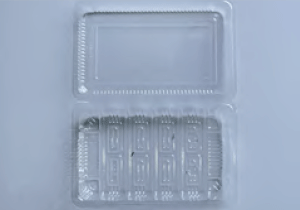

Transparent container stain inspection

Workpiece

LB-300X150SW

Uniform diffused lighting illumination from a wide light emitting surface minimizes the effect of unevenness and clearly images stains.

Image

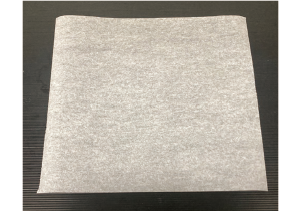

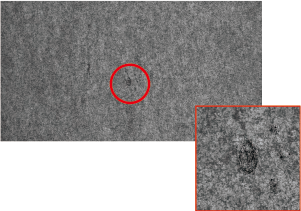

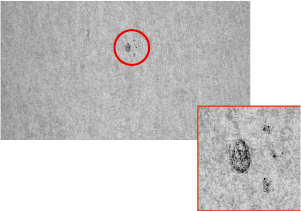

Dirt on fiber workpieces

Workpiece

LNSD-300SW(A)

The light-emitting surface is narrow and the angle of light to the surface is small, reducing the overall light hitting the paper and making it difficult to see the dirt.

LB-300X150BL

The large light-emitting surface allows light to hit the paper from multiple directions, making it easier to see the difference between stains and paper.

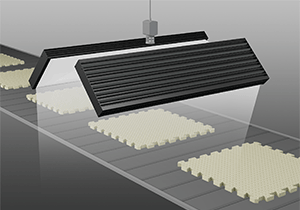

Diffused dome illumination

Stain inspection of non-woven fabrics, etc.

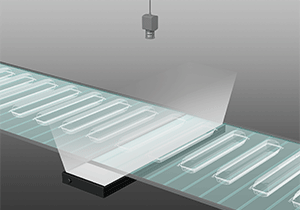

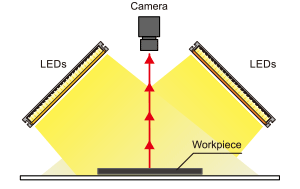

Example Configuration

Uniform diffused lighting is illuminated from 2 directions to reproduce the dome effect. Images can be captured with minimal shading and halation effects on uneven surfaces.

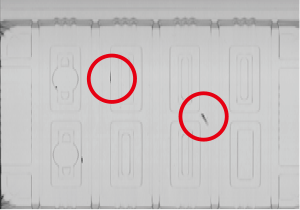

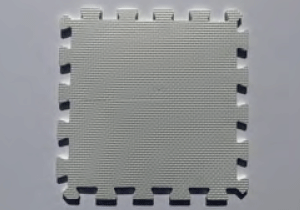

Scratch inspection of uneven mats

Workpiece

LB-300X150SW×2 units

Clear imaging of scratches by suppressing shadows on uneven surfaces.

Image

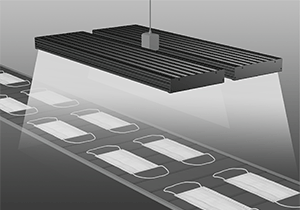

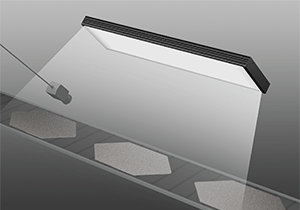

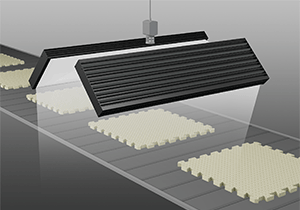

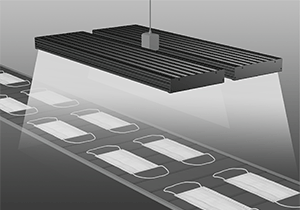

Wide-range uniform illumination

Print inspection on satin metal

Lighting for robot picking, etc.

Example Configuration

Uniform diffused lighting is illuminated on the same axis as the camera. Also effective for wide-area imaging, such as wide workpieces, etc.

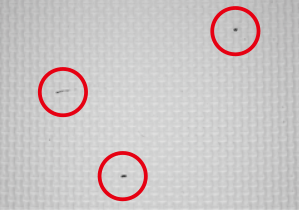

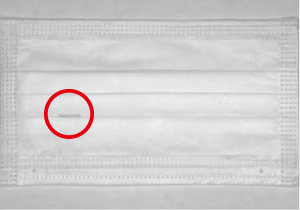

Foreign contamination inspection of non-woven fabrics

Workpiece

LB-300X150SW×2 units

Clear imaging of foreign contamination that overlaps the shadows of the seams.

Image

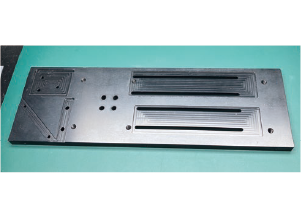

Surface inspection of metal machined parts

Workpiece

Aluminum machined parts

(black anodized aluminum)

LNSD-300SW(A)

Not uniformly illuminated. The cutting marks on the machined surface stand out.

LB-300X150BL

Uniformly illuminated to capture images with no cutting marks visible.

Data

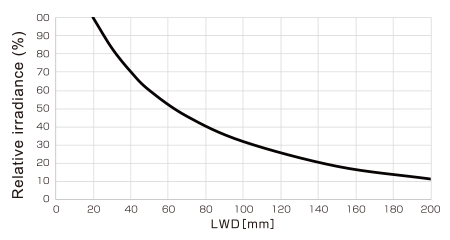

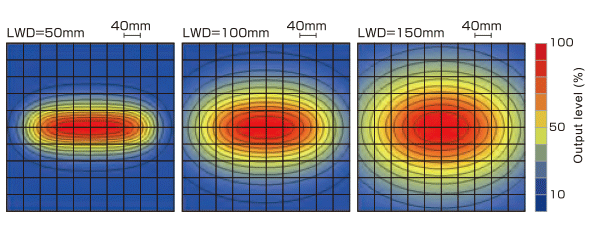

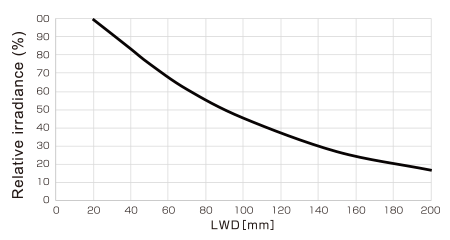

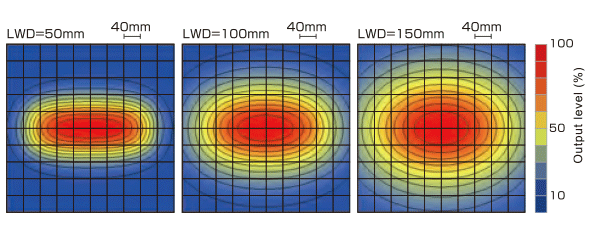

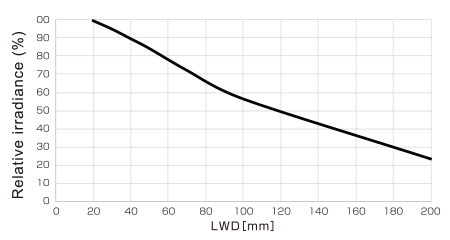

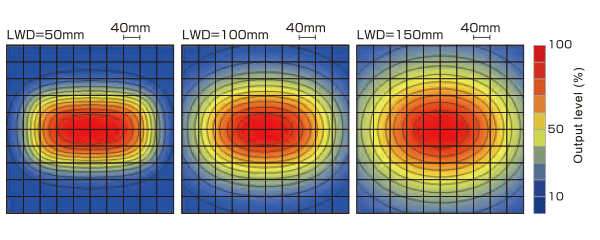

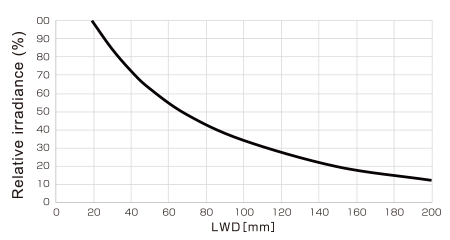

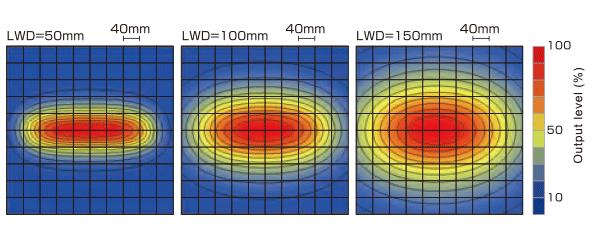

Relative Irradiance Graph and Uniformity

Graphs shown are for reference only. Not a guarantee of product quality.

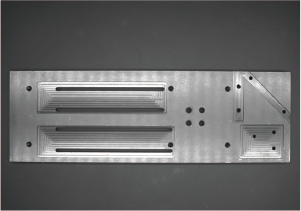

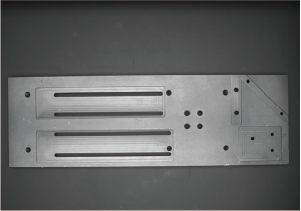

LB-300X50SW (Standard Type / Emitting Width 50 mm / White)

LB-300X100SW (Standard Type / Emitting Width 100 mm / White)

LB-300X150SW (Standard Type / Emitting Width 100 mm / White)

LB-H-300X50SW (High Power Type / Emitting Width 50 mm / White)

*1 Irradiance on the optical axis

*2 Illuminating distance between the light unit and the workpiece

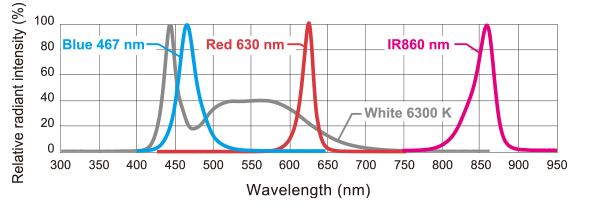

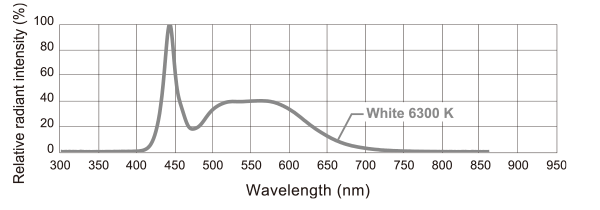

Spectral distribution

LB Series Standard Type

LB Series High Power Type

Options

Please refer to each product page for details and lineup of optional products.

Diffusion Plates

Light characteristics can be changed by changing the diffusion plate.

The DF-LB Series diffusion plates have lower uniformity and higher transmissivity than the standard type diffusion plates installed at the time of shipment.

*For high power type lighting, DF-LB Series diffusion plates are installed at the time of shipment.

Polarizing Plates

These are used together with a polarizing filter attached to the camera lens to eliminate surface glare.

Protective Plates

Protects the emitting part of the light unit.

* It is not intended to protect against dust or water.Products

-

Machine Vision Applications

Ring

Low-angle Ring

Waterproof Ring

Bar (Area)

Low-angle Square

Flat

Flat Dome

Line Pattern

Dome

Coaxial

Cylinder

High Power Strobe

UV Lights [Ultraviolet Lighting] / Violet Light

IR Lights [Infrared Lighting] (under 1000nm)

IR Lights [Infrared Lighting] (over 1000nm)

Spot

Fiber Heads

Light Source Unit

Line (Convergent Lighting)

Line (Diffused Lighting)

Line (Oblique Angled Lighting)

Reference Light Source

Lights for Fringe Interference Inspection

Custom Order Product

Intensity Control Units [Light Units with Intensity Control Unit ]

OLED(CCS-LT)

Effilux Products

Basler Camera Light Series

- BCL Series (Bar Light)

- BCR Series (Ring Light)

- BCBL Series (Flat Light)

- BCF Series (Flood Light)

- BCL Series (Bar Light) Diffusion Plates

- BCR Series (Ring Light) Diffusion Plates

- BCF Series (Flood Light) Transparent Plate

- BCL Series (Bar Light) Light Polarizing Plates

- BCR Series (Ring Light) Polarizing Plates

- BCF Series (Flood Light) Polarizing Plates

- BCR Series (Ring Light) Light Adapter

- BCL Series (Bar Light) Light Bracket

- Basler Camera Light dedicated cable

-

Control Units

Digital Control Units

Strobe Unit

High Power Strobe Control Unit

PoE Enabled Controller

Controller with EtherNet/IP Interface

LED Light Controller

Control Units [for the HLV Series]

High-capacity Constant-current Control Units

High-capacity Analog Control Unit

Control Units [for CCS AItec]

-

Cables

Straight Cables

2-way Cables

4-way Cables

Robot Cables

2-way Robot Cables

4-way Robot Cables

Straight Cables [EL connector type]

2-way Cables [EL connector type]

Extension Cable [for PF Series]

Straight Cables for metal connector (7 pins)

Straight Cables for metal connector (37 pins)

Straight Cables for M12 connector

External Control Cables

Relay Connector

AC Power Cable

-

Options

Filters

Diffusion Plates

- Diffusion Plates [for Ring Lights]

- Diffusion Plates [for LDR-PF Series]

- Diffusion Plates [for LDR-PF-LA Series]

- Diffusion Plates [for Low-angle Ring Lights]

- Diffusion Plates [for Bar Lights]

- Diffusion Plates [for LDL-PF Series]

- Diffusion Plates [for HLDL3 Series]

- Diffusion Plates [for LB Series]

- Diffusion Plates [for Coaxial Lights]

- DF Series

- DF80 Series

Polarizing Plates

- Polarizing Plates [for Ring Lights]

- Polarizing Plates [for LDR-PF Series]

- Polarizing Plates [for Bar Lights]

- Polarizing Plates [for LDL-PF Series]

- Polarizing Plates [for HLDL3 Series]

- Polarizing Plates [for LB Series]

- Polarizing Plates [for Coaxial Lights]

- Polarizing Plates [for IR Series Infrared Lights (over 1000-nm type)]

- PL Series (FASTUS)

Light Control Films

Protective Plates

Adapter [for the CSR Series]

Lens Attachment Rings

Fixtures

Fixtures

Converter

Coaxial Units

Reflection Plate

Condenser lens

-

Lenses

Telecentric Lenses

Macro Lenses

-

Software Tools

Program for controllers

Version Upgrade for controllers

Application note for controllers

-

Agri-Bio Lighting

LED Light Units for Plant Research

ISL-150X150 Series Unit

ISL-150X150 series cables

-

Human Vision Inspection and Microscope Applications

LED Light Units for Microscopes

Request Free Trial

Request Free Trial Request Quotation

Request Quotation Inquiry Form

Inquiry Form Locations

Locations