HPDS / HPDM Series

[Not available in Japan]

"FALUX sensing"* enables monitoring of brightness and feedback control.

*Included in HPDS Series only.

Provides diffused light evenly through the dome-shaped reflective panel.

Features

Built-in “FALUX” circuit to correct variations in brightness

*Included in all models.

Using the constant current circuit dependent on the input voltage, variations in the forward current of individual LEDs are corrected for uniform brightness.

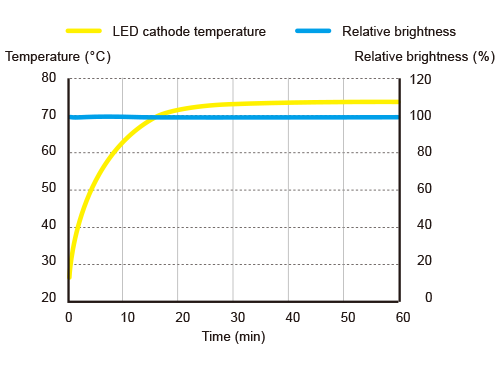

Meanwhile, the temperature compensation circuit compensates for fluctuations in brightness due to increases in temperature after lighting or changes in the ambient temperature.

FALUX not included

In order to reduce LED forward voltage variations, the LEDs needed to be sorted according to their Vf measurement. Moreover, illumination efficiency dropped as the temperature increased, reducing the brightness.

FALUX included

The brightness of each LED is fixed, virtually eliminating variations in brightness following increases in temperature. Whether with continuous illumination or ON/OFF control, brightness remains fixed.

Equipped with “FALUX sensing” for monitoring brightness and temperature through sensing

*Included in HPDS Series.

LED brightness sensing is performed using multiple built-in photodiodes. This allows for accurate measurement of LED brightness not only during continuous illumination but also with short period illumination. Absolute brightness is stored in the lighting’s internal memory to allow for instrumental error adjustment.

"FALUX sensing" also makes it possible to measure both the LED brightness of lighting and the internal temperature, and then to monitor those measurements on the controller side. Based on the monitored values, feedback control can also be performed from the OPPF or OPPD Series controller, making it possible to maintain the factory default brightness for around 40,000 hours.

Supports applications for a wide variety of industries

It is bright and even if the distance from the workpiece to the Light Unit is changed, there is little change in the uniform region. Therefore, it can be used in a wide range of industries.

Semiconductor industry (Circuit board)

LED color : white

Electronic parts industry (Condenser)

LED color : white

Food industry (Chocolate)

LED color : white

Packaging industry (Top of a drink container)

LED color : white

Illuminates diffused light at high output

Light from the surface-mounted LEDs is diffused inside the dome-shaped reflective panel. The diffused light from the wide uniform region is illuminated evenly.

FALUX / FALUX Sensing Technology

Did you know the LED brightness varies depending on ambient temperature?

Problem 1

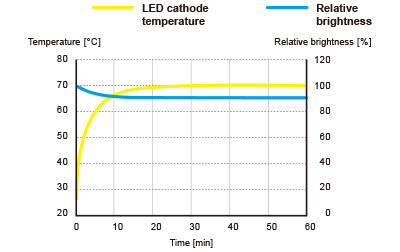

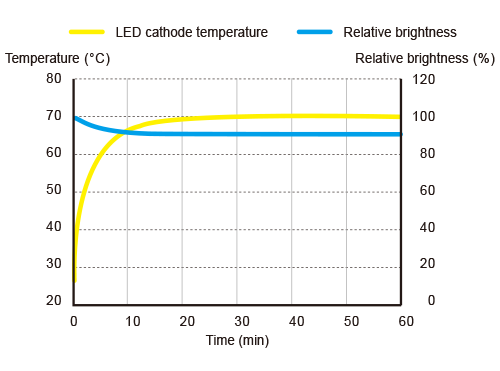

Temperature changes influence brightness.

Increased temperature due to self-heating and changes in ambient temperature as air conditioning equipment starts up can affect the brightness of LED lighting.

`FALUX` Technology

Solution 1

Our FALUX technology automatically compensates for brightness fluctuations due to temperature changes.

Using the constant current circuit dependent on the input voltage, variations in the forward current of individual LEDs are corrected for uniform brightness. The temperature compensation circuit compensates for fluctuations in brightness due to changes in temperature.

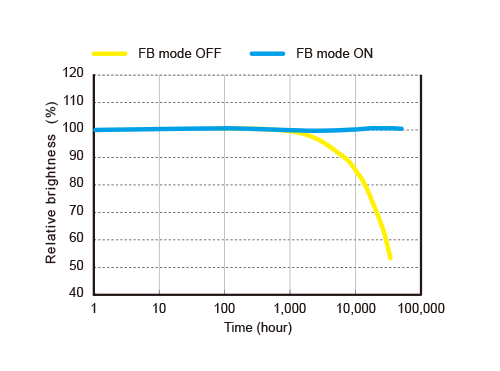

Did you know the LED brightness will be decreased after 1,000 hours operation?

Problem 2

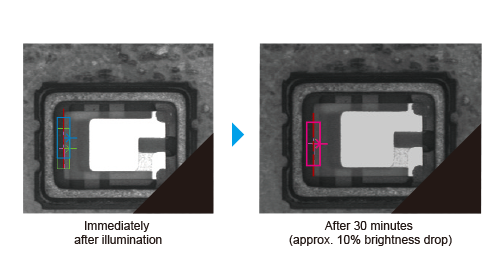

Need consistent brightness for long-term use.

On a fully operational 24-hour line, LEDs begin to lose brightness after about 1,000 hours, causing costly inspection failures.

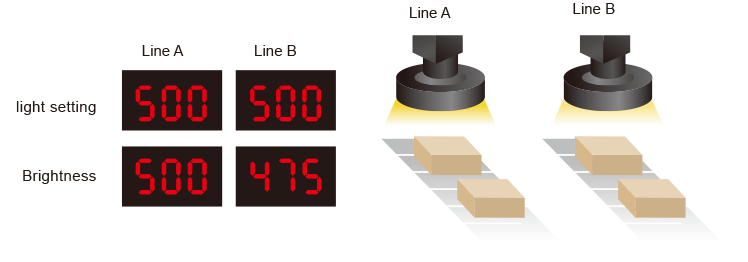

Problem 3

Need consistent level of brightness across multiple light units.

Actual brightness of light unit is different on each inspection line even though the setting is the same.

`FALUX Sensing` Technology

Solution 2

Brightness is automatically adjusted to maintain initial settings after receiving a low brightness alarm.

Solution 3

Solved by using an absolute brightness monitor + copying setting values across all units

FB control

Eliminates variations over long periods. FB control fine tunes the output voltage to match the standard brightness. Output as a feedback error when the upper or lower output voltage adjustment limit is reached.

Problem 4

Different settings are needed one after another

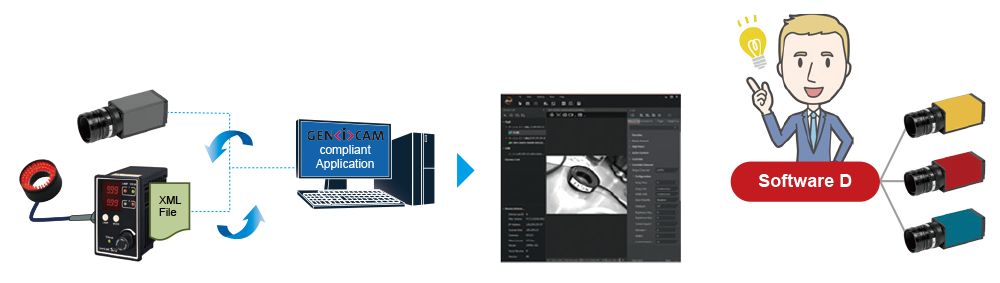

Different settings or programs must be used depending on the camera, requiring extra time and cost.

Solution 4

Easy configuration with our original controllers.

Connection example (

Products

-

Machine Vision Applications

Ring

Square

Bar (Area)

Flat

Dome

Cylinder

Box

Spot

Line (Convergent Lighting)

Line (Diffused Lighting)

Line (Oblique Angled Lighting)

UV Lights [Ultraviolet Lighting] / Violet Light

IR Lights [Infrared Lighting] (under 1000nm)

Custom Order Product

Intensity Control Units [Light Units with Intensity Control Unit ]

OLED(CCS-LT)

Effilux Products

Basler Camera Light Series

- BCL Series (Bar Light)

- BCR Series (Ring Light)

- BCBL Series (Flat Light)

- BCF Series (Flood Light)

- BCL Series (Bar Light) Diffusion Plates

- BCR Series (Ring Light) Diffusion Plates

- BCF Series (Flood Light) Transparent Plate

- BCL Series (Bar Light) Light Polarizing Plates

- BCR Series (Ring Light) Polarizing Plates

- BCF Series (Flood Light) Polarizing Plates

- BCR Series (Ring Light) Light Adapter

- BCL Series (Bar Light) Light Bracket

- Basler Camera Light dedicated cable

IR Lights [Infrared Lighting] (over 1000nm)

Reference Light Source

Lights for Fringe Interference Inspection

-

Agri-Bio Lighting

LED Light Units for Plant Research

ISL-150X150 Series Unit

ISL-150X150 series cables

-

Human Vision Inspection and Microscope Applications

LED Light Units for Microscopes

-

Power Supplies

High Power Strobe Control Unit

Digital Control Units

Analog Control Units

LED Light Controller

Control Units [for the HLV Series]

Strobe Unit

High-capacity Analog Control Unit

High-capacity Constant-current Control Units

Controller with EtherNet/IP Interface

PoE Enabled Controller

Control Units [for CCS AItec]

Program for controllers

-

Cables

Extension Cable [for PF Series]

Straight Cables

2-way Cables [EL connector type]

4-way Cables

Robot Cables

Straight Cables [EL connector type]

2-way Cables [EL connector type]

Straight Cables for metal connector (7 pins)

Straight Cables for metal connector (37 pins)

Straight Cables for M12 connector

External Control Cables

Relay Connector

-

Options

Filters

Polarizing Plates

- Polarizing Plates [for IR Series Infrared Lights (over 1000-nm type)]

- Polarizing Plates [for HLDL3 Series]

- Polarizing Plates [for LB Series]

- Polarizing Plates [for LDR-PF Series]

- Polarizing Plates [for LDL-PF Series]

- Polarizing Plates [for Ring Lights]

- Polarizing Plates [for Bar Lights]

- Polarizing Plates [for Coaxial Lights]

- PL Series (FASTUS)

Diffusion Plates

- Diffusion Plates [for HLDL3 Series]

- Diffusion Plates [for LB Series]

- Diffusion Plates [for LDR-PF Series]

- Diffusion Plates [for LDL-PF Series]

- Diffusion Plates [for Ring Lights]

- Diffusion Plates [for Low-angle Ring Lights]

- Diffusion Plates [for Bar Lights]

- Diffusion Plates [for Coaxial Lights]

- DF80 Series

- DF Series

- Diffusion Plates [for LDR-PF-LA Series]

- DF-ISL-165X165 Series

Light Control Films

Adapter [for the CSR Series]

Lens Attachment Rings

Fixtures

Converter

Protective Plates

Coaxial Units

Fixtures

Reflection Plate

Condenser lens

-

Lenses

Telecentric Lenses

Macro Lenses

Request Free Trial

Request Free Trial Request Quotation

Request Quotation Inquiry Form

Inquiry Form Locations

Locations